Week 05

3D Scanning and Printing

Brief Overview

In this group assignment we have a task to test design rule file on our 3D printer, to test various parameters and sample files, observe the print quality and understand the possiblities and limitations of 3D printer.

We have documented our work and observation in this assignment

Primary Objective of this Week:

During this week's group assignment, our focus was to test the sample design rules file to know about the capabilities of our 3D printer. The primary objectives of the group assignment were as follows:

Understand and know how to operate 3D printer

Safety Precaution while using machine

To test design rules on our 3D Printer

To Document our work and explain what are the Possiblities and Limitation of our printer

Our understanding from test print the design rules

Know your Printer:

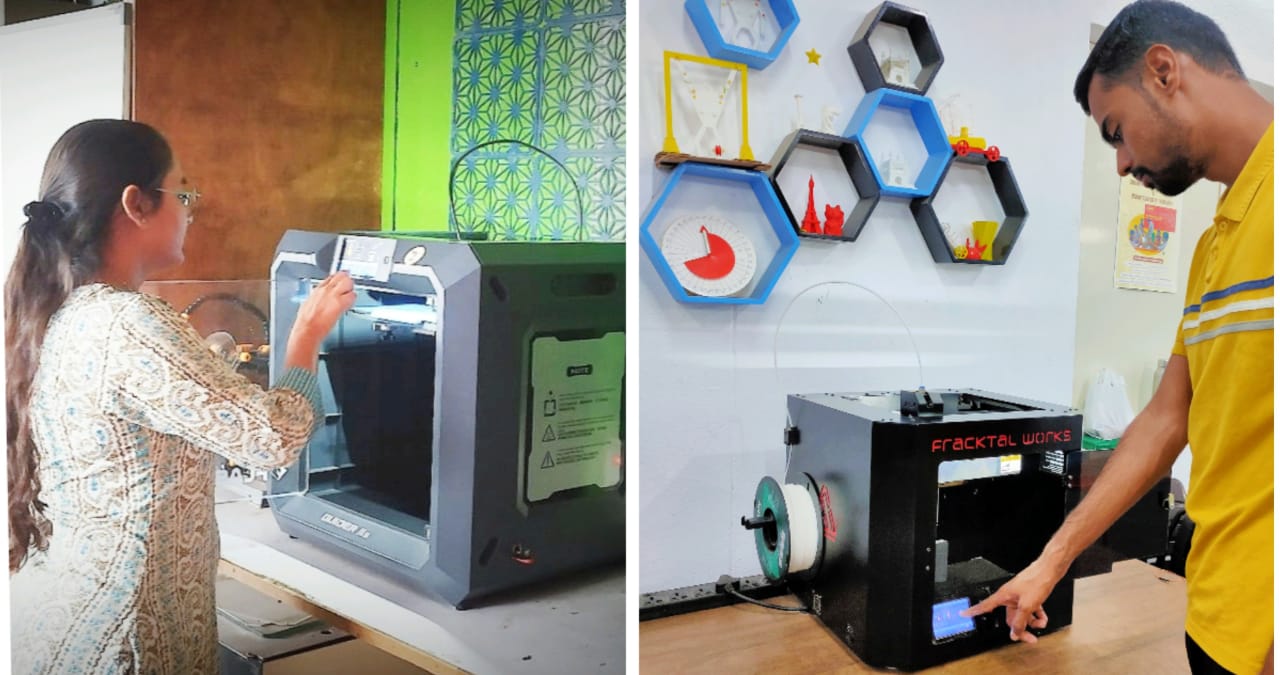

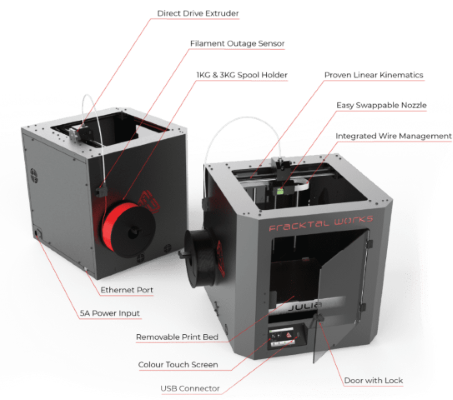

Fractal Works : Julia Advanced

Fracktal Works Julia Advanced 3D printer: With a fully integrated system of hardware, software and materials, it is the most reliable, innovative and easy to use 3D printer on the market. An all-in-one solution that combines precision linear motion, integrated high-end electronics, heating and material management systems in a beautiful aesthetic desig

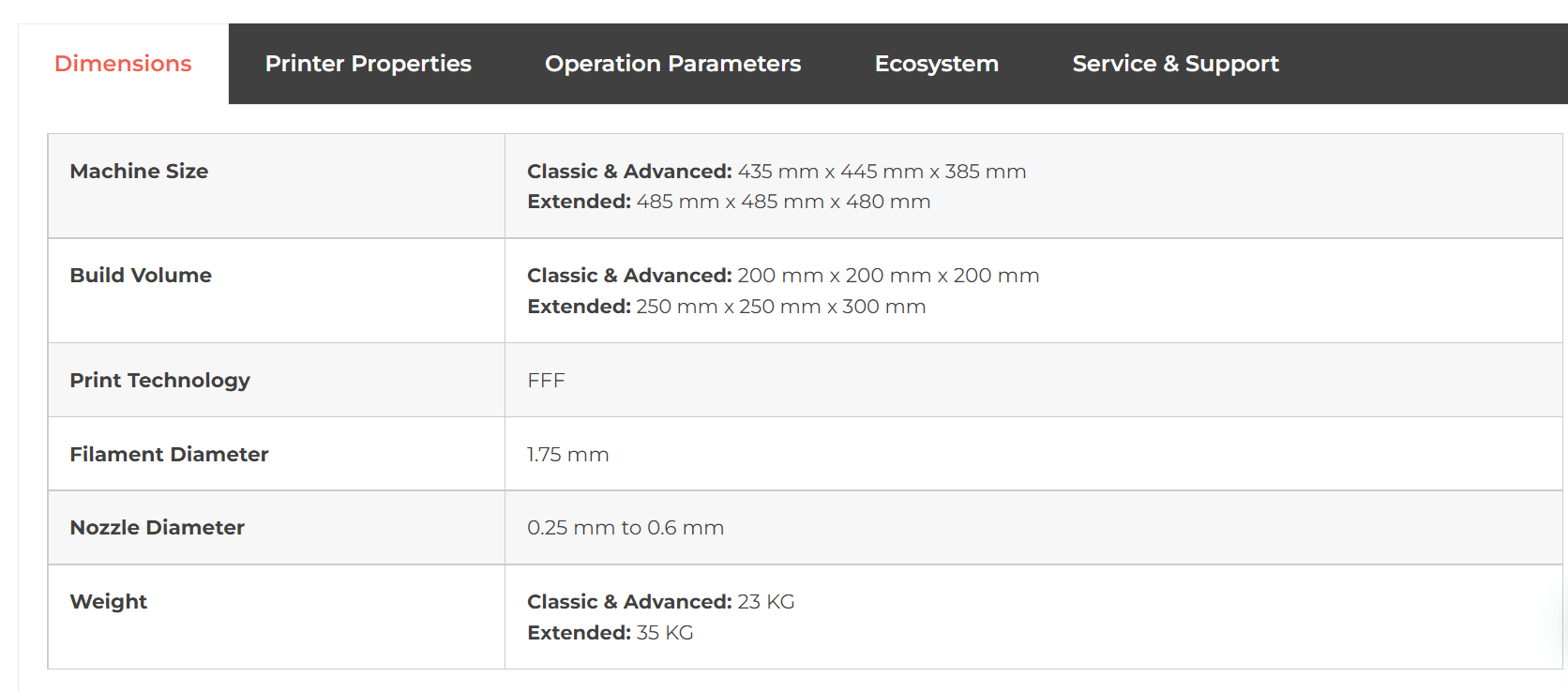

Printer Dimensions

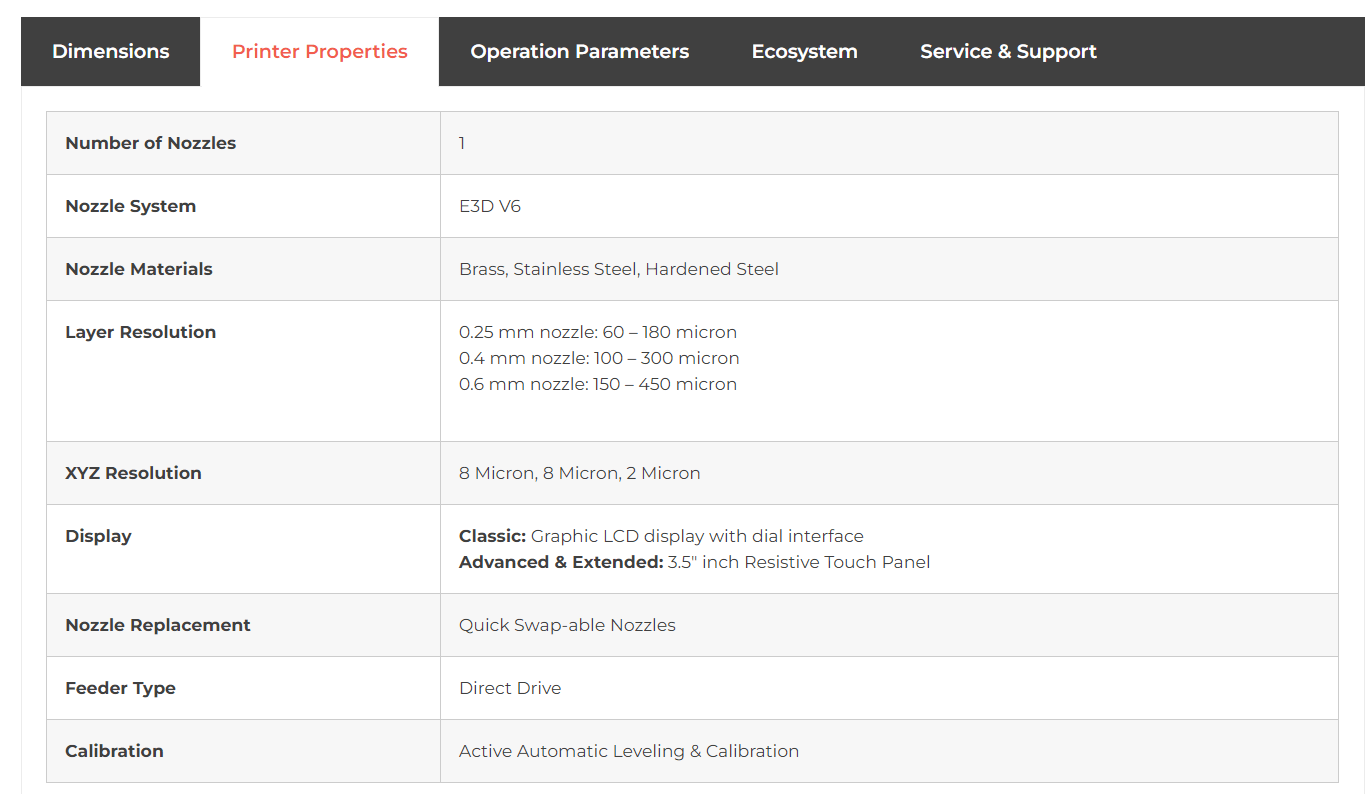

Printer Properties

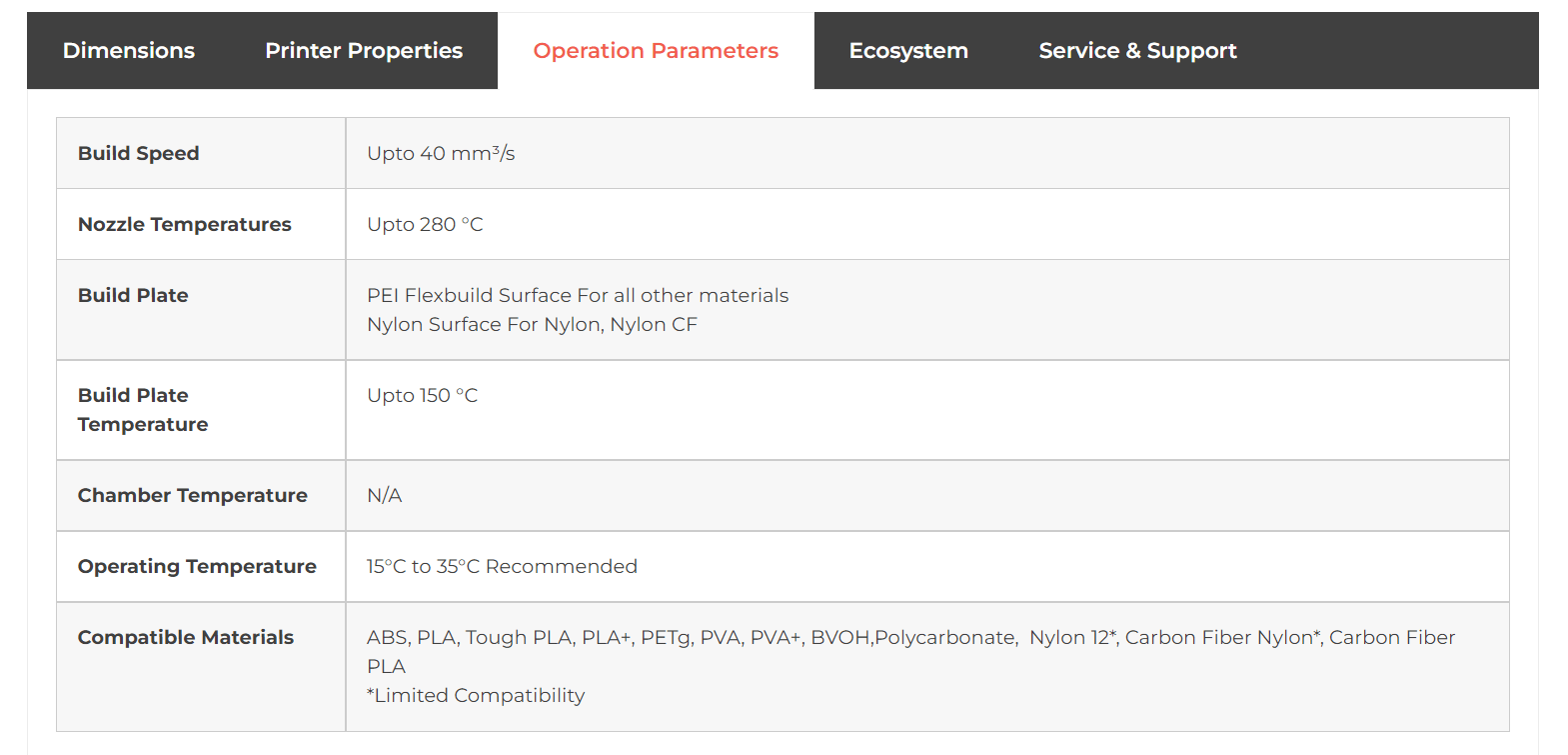

Printer Parameters

Printer Ecosystem

3D Printer Safety Precautions

Operating a 3D printer involves potential risks. Please follow these precautions to ensure a safe and enjoyable experience:

Environment and Ventilation

- Location: Place the printer in a well-ventilated area.

- Ventilation: Use proper ventilation to remove fumes.

- Fire prevention: Keep a fire extinguisher readily available.

Printing Process

- Monitor printing: Don't leave the printer unattended.

- Material handling: Use caution when handling hot filament and resin

- Post-processing: Follow proper procedures for post-processing.

Additional Tips

- Read the manual:Thoroughly read and understand.

- Use recommended materials: Stick to materials recommended.

- Maintain your printer: Regularly clean and maintain.

- Stay informed: Keep yourself updated on safety best practices.

Remember, safety is paramount. By following these precautions, you can minimize risks and enjoy a safe and successful printing experience.

Design Rules

Design Rules for 3D Printing

Design rules for 3D printing are guidelines that ensure your model can be successfully printed on a particular 3D printer. They take into account the limitations of the printing process, such as the minimum layer thickness, the maximum overhang angle, and the supported resolution.

-

Bridging:

- Unsupported horizontal spans.

- Minimize length, use thicker walls for longer spans.

- Avoid thin, long bridges to prevent sagging or breakage.

- Consider redesigning to eliminate bridging if possible.

-

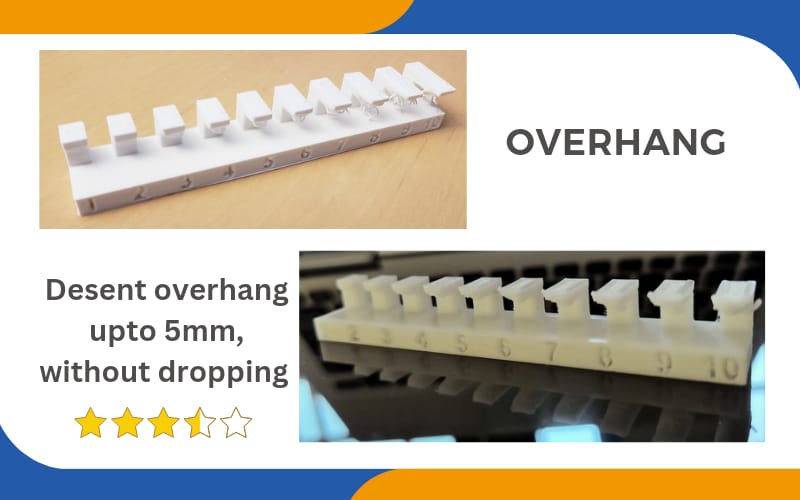

Overhang:

- Jutting sections without underlying support.

- Limit angles to avoid support structures.

- Typical FDM limit is around 45 degrees.

- Use support structures or adjust angles for complex overhangs.

-

Angle:

- Angle between vertical surface and horizontal plane.

- Consider minimum angles for features like holes and slots.

- Steeper angles might require support, impacting print time and quality.

- Adjust angles or redesign features for printability.

-

Surface Finish:

- Quality and smoothness of the printed part's exterior.

- Layer lines are inherent, affecting surface finish.

- Use higher resolutions for smoother surfaces (increases print time).

- Optimize for post-processing techniques like sanding or smoothing if needed.

-

Dimension and Wall Thickness:

- Maintain minimum wall thickness based on material and printer.

- Too thin walls are weak, excessively thick walls waste material and time.

-

Dimension:

- Ensure dimensions fit within the printer's build volume.

- Find the balance between strength, printability, and material efficiency.

Conclusions from the Group Assignment

- Gained a comprehensive understanding of additive vs. subtractive manufacturing, including principles, processes, equipment, achievable complexity, producible features, material suitability, and finishing requirements.

- Explored the advantages and disadvantages of FDM (Fused Deposition Modeling) and various materials used with it.

- Familiarized with the features and operation of the Fracktal Works Julia Advanced 3D printer, including control panel functionalities.

- Successfully tested design rules by printing components and the 3Dbenchy model using PLA filament, comparing printed objects with reference dimensions.

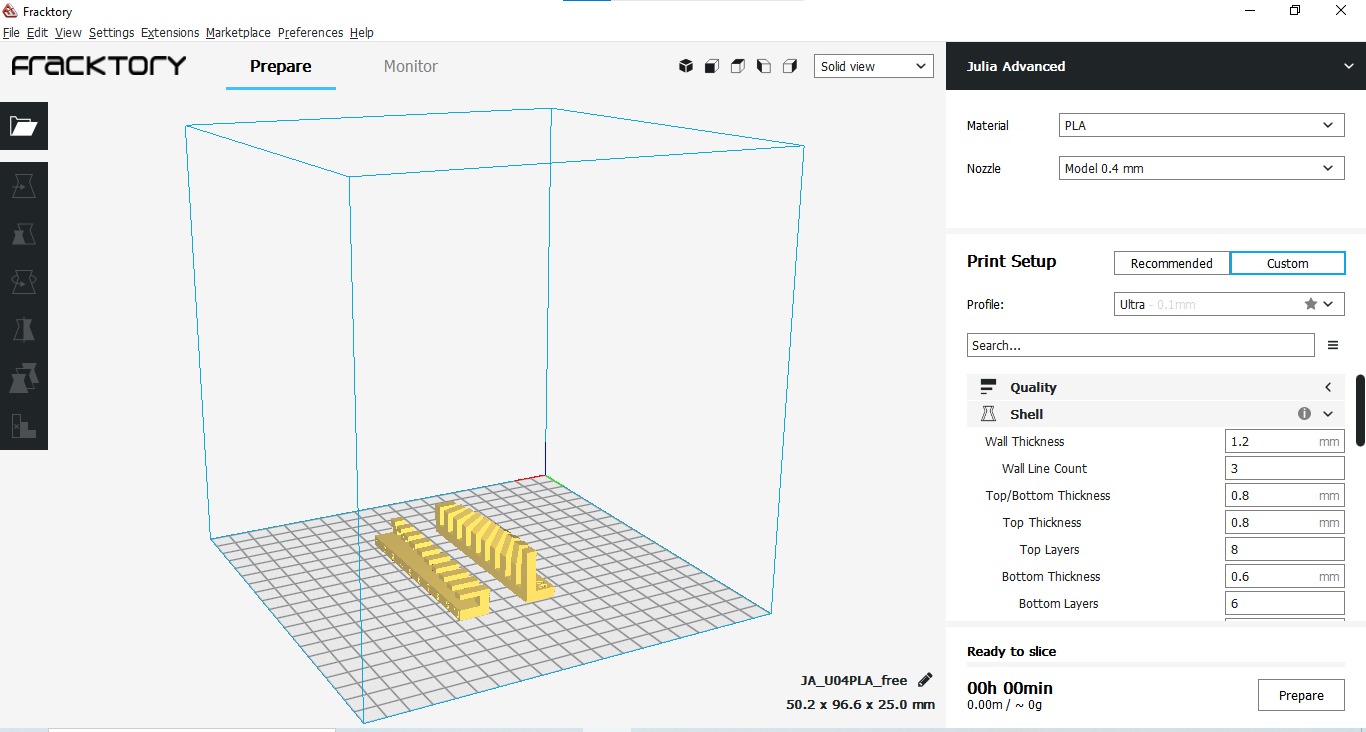

- Learned the process of generating G-code for 3D printing using Fracktory slicing software, including loading STL files, setting parameters, and generating G-code for each object.

- Gained practical experience in setting up the 3D printer, including bed calibration, temperature control, flow rate and feed rate adjustment, and filament extrusion.

Overall, the group assignment provided valuable hands-on experience with 3D printing technology, allowing us to understand the process, experiment with different functionalities, and gain insights into the capabilities and limitations of our specific 3D printer.